.jpg)

|

Ningbo Yuxiang Magnetics Co., Ltd.

|

lifting magnet

| Price: | 2.0~1000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Magnetic Lifter was made of metal parts and strong permanent magnet.

It can hold up 100-5000kgs weight goods according to different model.

This is magnetic lifter, it is made of High-performance magnetic material, and it used to make it smaller, lighter forces, a powerful suction.

Unique magnetic circuit design, remanence almost zero. Safety factor,and is rated lifting of 3.0-3.5 times. A switch handle security button, one-handed operation, to facilitate safety.

No need electricity, magnetic long-lasting popularity, the use of safety. In field operations, widely used in the lifting of steel handling, the formation of mechanical parts, various molds and the installation and removal.

3. 1During operation, you should clear away the components surface such as rust

Unique magnetic circuit design, remanence almost zero. Safety factor,and is rated lifting of 3.0-3.5 times. A switch handle security button, one-handed operation, to facilitate safety.

No need electricity, magnetic long-lasting popularity, the use of safety. In field operations, widely used in the lifting of steel handling, the formation of mechanical parts, various molds and the installation and removal.

1.APPLICATION AND FEATURES

Permanent Magnetic Lifters Model PML is mainly used for connecting component

During lifting and handling operation. They can hoist moving iron block, cylindrical

And other magnetic material. They are easy for operation, safe in handling, lightly

And ingeniously structured. Hence they are widely used as hoisting devices in factories,

Docks warehouses and transportation industries. By using them, you can improve

Your working conditions and increase your working efficiency.

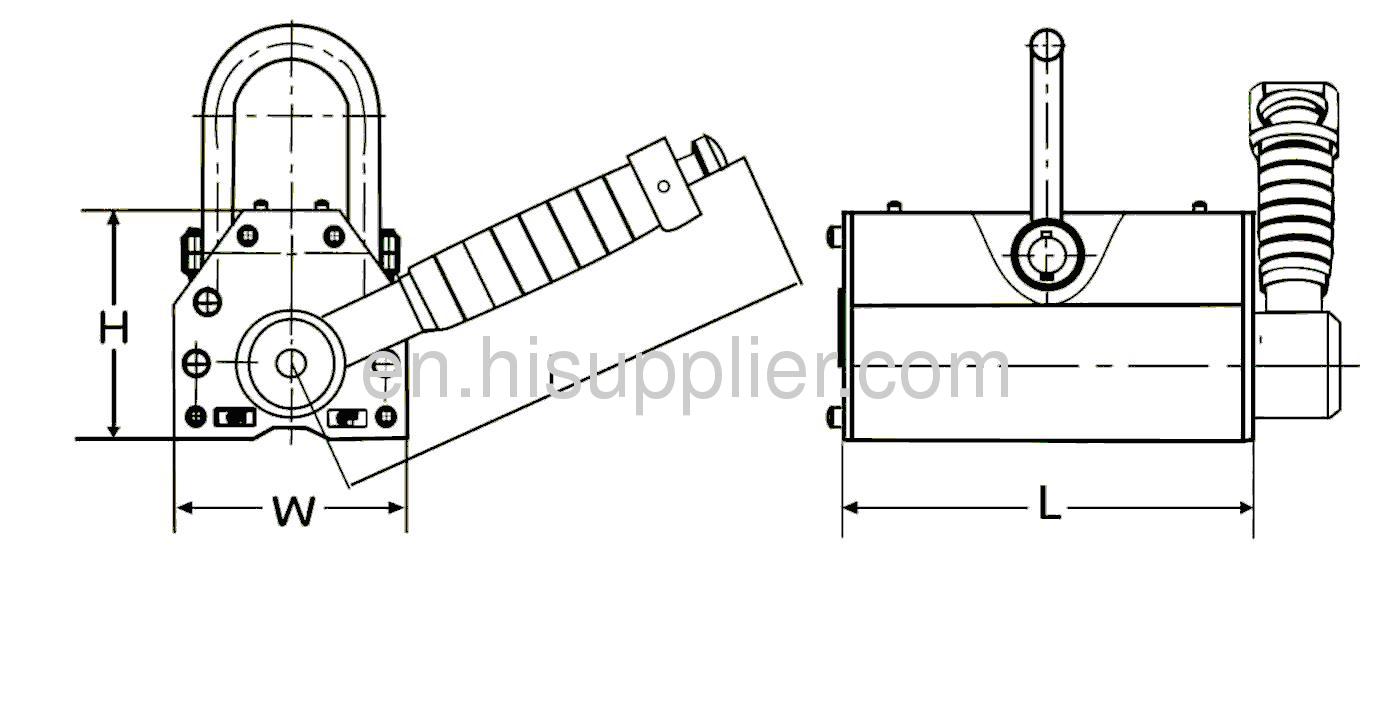

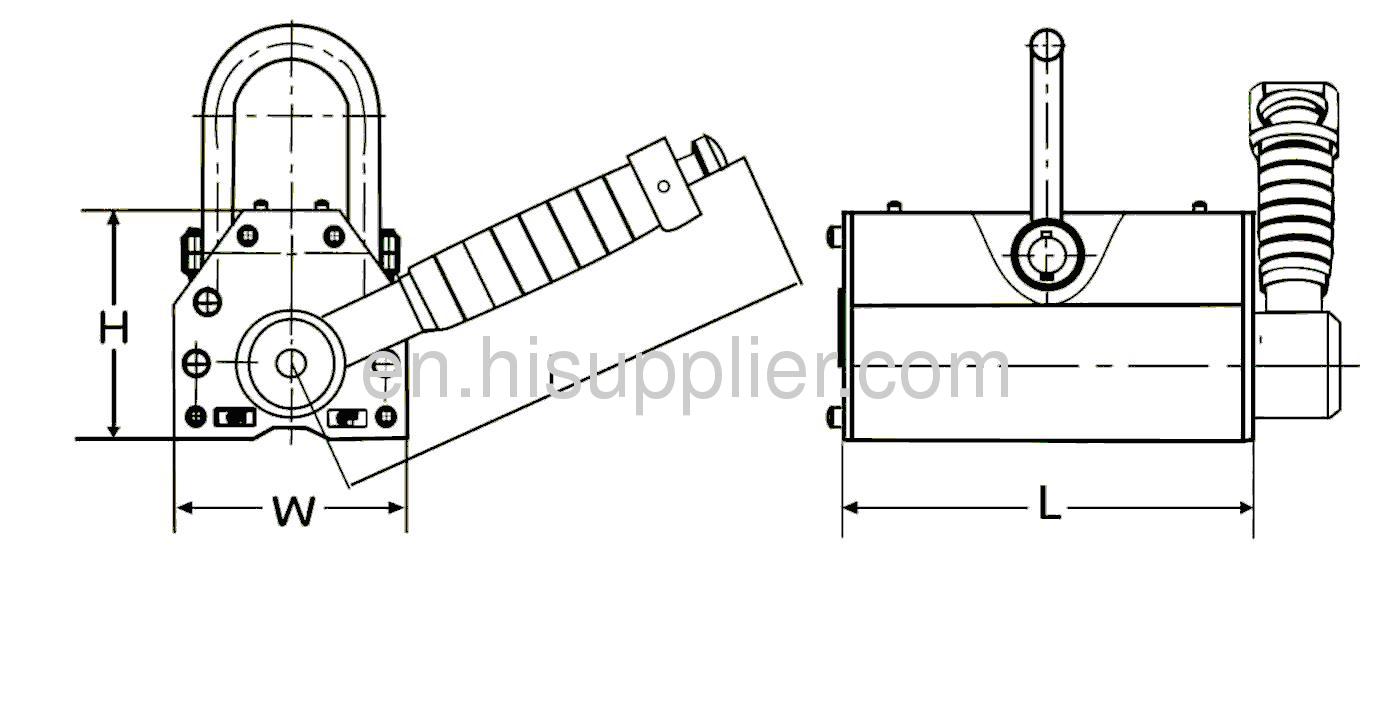

2.CONSTRUCTION AND SPECIFICATION

construction: MODEL PML Permanent Magnetic Lifter has strong magnetic

path produced by NdFeB magnetic materials. On and off the magnetic path is

controlled by turning the manual nozzle .There are shackles on the top of Magnetic

Lifting Hoist for lifting, a veto slot on the holding face for holding cylindrical

Component firmly.

2.1Specifications

MODEL | Ratedlifting strength | Cylindrical Liftingstrength | Maxpull-off strength | W | L | H | I | Operation temperature | Deadweight |

(Kgf) | (Kgf) | (Kgf) | (℃) | (Kg) | |||||

PML-1 | 100 | 30 | 300 | 64 | 92 | 70 | 145 | <80 | 3 |

PML-3 | 300 | 100 | 900 | 88 | 165 | 96 | 176 | <80 | 10 |

PML-6 | 600 | 200 | 1800 | 118 | 216 | 118 | 219 | <80 | 20 |

PML-10 | 1000 | 300 | 3000 | 148 | 264 | 138 | 266 | <80 | 37 |

PML-20 | 2000 | 600 | 6000 | 168 | 397 | 168 | 380 | <80 | 80 |

PML-30 | 3000 | 1000 | 9000 | 226 | 443 | 216 | 512 | <80 | 160 |

PML-50 | 5000 | 15000 | 290 | 582 | 265 | 627 | <80 | 325 | |

PML-60 | 6000 | 18000 | 290 | 713 | 265 | 707 | <80 | 398 |

3. 1During operation, you should clear away the components surface such as rust

and burr. The centerline of lifter had better overlap with the centerline of component.

Then place the Magnetic Lifting Hoist on the face of component, turn the nozzle from

"OFF" to "ON" until "holding" .Make sure that the security key on the handle is auto

-matically locked, and then start to hoist.

3.2 During lifting and handing components, overloading is forbidden. Nobody is

allowed to pass through under the component held by Magnetic Lifter. Components

temperature and ambient temperature shall be between +80°C to -40°C. No strong

vibration and impact.

3.3 When lifting and handling cylindrical components, Keeping the cylindrical

Surface contacting the Vee slot of lifter on two lines, the actual lifting capacity will

Generally be 30% of the rated lifting capacity.

3.4 When lifting and handling operation is finished, press down the bottom to

disengage the security key from the security pin, then turn the handle "ON" to "OFF"

until "Release". The lifter is now in the neutral condition, it can be taken away

from the component.

4.Main factors which influence the lifting capacity of permanent Magnetic

Lifter.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Permanent Lifting Magnet

Lifting Equipment

Lifting Chains

Lifting Chain

Lifting Platform

Lifting Column

More>>

.jpg)

.jpg)

.jpg)

.jpg)